Coating Failures / Painting Flaws / Coating Degradations / coating defects

All steel structures and auxiliaries in every industry are protected with Industrial Coatings / Cathodic Protection / Thermal Spray / Hot-dip Galvanizing and with many modern methods. The following Industrial sectors are protected with high-performance Protective Coatings and other alternate protection methods.

Oil / Gas (Refineries / LNG & LPG Plants / Pipelines), Petrochemical (All Chemical Plants), Marine / Shipbuilding, Small, Medium & Heavy Industries, power plants, onshore plants, offshore plants, cross country pipelines (Gas / Potable water), Storage Tanks, Automobile, Bridges, Railway, High Voltage Transmission Towers, underground pipelines, Hi-rise & Sky scrapper commercial buildings, Building Facades, other processing industries

Qualified and approved painting contractors were engaged for appropriate industry corrosion protection. Entire surface preparation and coating application performed by coating contractors that are regularly inspected / Tested and accepted by Qualified and Certified Coating Inspectors (FROSIO / SSPC / NACE / ICORR / BGAS or equivalent).

During and after coating application, the sort of coating failures inevitable with various known and unknown reasons and actions. Those coating defects or failures are primarily instigated by coating applicators (poor surface preparation and wrong application techniques etc.,) however in few instances, the Coating suppliers, wrong specification contents, and environmental factors are accountable for coating failures in our industries.

All coatings will fail eventually regardless of the right quality of materials used, proper Surface Treatment, and coating application performed. In the selection of a coating system, environmental influences may impede the coating performance thus resulted in possible premature coating failures or coating degradations.

“Time to Failure” must be considered and evaluated but not the “Coating System would Fail”. Many coating systems fail before the coating lifetime which is termed “premature Coating Failures” or Coating Degradations

The premature coating failures are caused by:

Improper Surface Treatment or Preparation (by applicator)

Improper Coating Application methods (by applicator)

Wrong coating system selection (by facility owner)

Inferior quality coating ingredients (by paint supplier)

Structural Engineering design (Engineers / Consultant appointed by Facility Owner)

The coating system was specified for the wrong environment (Facility Owner)

In New construction or Maintenance projects, regardless of intensive efforts emanated by many parties (Owner / Coating Suppliers, Painting Contractor / Painting Inspectors / Third party Inspectors, etc.), possible Coating Failures would appear. However, the sole responsibility held to Coating Inspectors is to minimize/mitigate the possible coating failures in any project or paint shops. Painting Inspectors are the focal point to determine the root cause of failures and to alleviate the futuristic failures from reoccurrence.

The primary role of any coating inspector is to avoid coating failures before starting / during and after coating application due to his continual presence in any assigned projects. If coating inspectors can identify and solves any violations as and when it appears, the coating failure percentage would be reduced drastically in any project.

Types of Coating Failures

Paint or Coating failures are further classified with various methods as per the following.

- Inside paint can or Tin

- During Application

- During curing

- During Service life

The above parameters can be divided into failures caused by mechanically induced failures, weather, corrosion, adhesion & blistering failures, light & radiation failures, chemically induced failures, heat-induced failures, and microbiological-induced degradation and failures.

Common coating failures are caused by either WET FILM COATING FAILURES or DRY FILM COATING FAILURES.

Wet Film Coating Flaws

- Sagging, Curtain & runs

- Dry Spray / Overspray

- Fish Eyes

Dry Film Coating flaws

- Holidays, low film thickness

- Orange peel

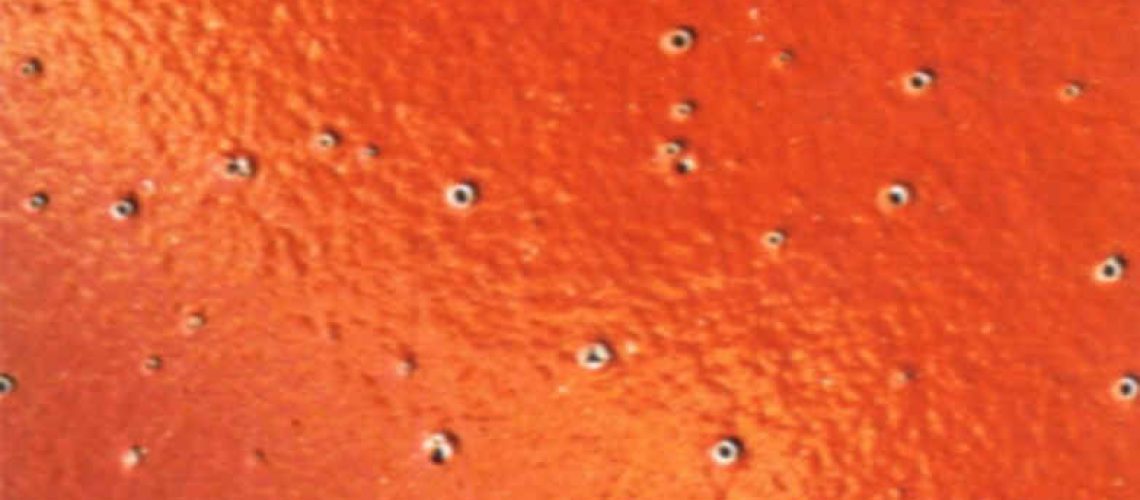

- Pinhole

- Popping

- Wrinkling/lifting

- Blooming / Blushing

- Pinpoint rusting

- Amine sweating / Amine blush / Carbonation

- Osmotic Blistering

- Cracking

- Delamination

- Bleeding

- Chalking

When do Coating defects appear?

- Paint defects can happen at any time when the paint is used

- Imperfections usually during one of two stages

- During the coating application (including the curing/drying phase)

- During coating service

- Few defects may only occur during application, such as sagging and fisheyes

- Certain defects are likely to happen during exposure, such as cracking, delamination, and blistering

What will cause paint defects?

- Insufficient surface preparation & surface profile is a recurrent source of paint defects

- Inadequately operated & preserved equipment, wrong application techniques, and poor planning will also spread the risk of paint defects

- All paint and coating systems are intended for a certain use and exposure. Incorrect specification may cause paint defects

- Oftentimes paint defects are due to a mixture of unfortunate conditions related to surface treatment, paint application, and exposure.

Written By

Venkat. R – Director-Industrial Coatings Training & Certifications

(SSPC / FROSIO / NACE / ICORR / BGAS Certified)

HTS COATINGS –SSPC / FROSIO Approved Training body (India & Global)

Mobile: +91-9176 618930 / Email: info@htscoatings.in / ahv999@yahoo.com

www.onlinecoatings.org / www.htscoatings.in / www.frosiotraining.com / www.sspcindia.in